تکامل ماشینهای مونتاژ جعبه: از دستی تا اتوماسیون

Introduction

The transition from manual box assembly to fully automated systems marks a significant evolution in the packaging industry. This shift has improved production speed, reduced labor costs, and enhanced environmental sustainability.

Historical Development

Box assembly began as a labor-intensive process, relying on manual labor for folding, gluing, and assembling boxes. The introduction of semi-automated machines reduced human intervention by automating certain steps like folding or gluing.

Technological Advancements

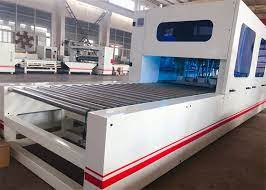

The advent of fully automated box assembly machines, equipped with advanced sensors, PLCs, and robotic arms, revolutionized the packaging industry. These machines can complete the entire box assembly process autonomously, with innovations like 3D printing and AI further enhancing their capabilities.

Impact on Production and Efficiency

Automation has significantly increased production speed and efficiency, enabling machines to operate around the clock and produce thousands of boxes per hour. This reduces the time products spend from production to market, meeting consumer demand more effectively.

Reduction in Labor Costs and Human Error

Automated machines have cut down labor costs and minimized human error, ensuring higher quality packaging and less waste.

Environmental Sustainability

Modern box assembly machines are more energy-efficient and can optimize box sizes to minimize waste, using recycled materials more effectively and reducing the environmental footprint of the packaging process.

Future Prospects

The future of box assembly machines lies in integrating technologies like machine learning, IoT, and advanced robotics, making machines smarter and more adaptable to changing production needs.

Conclusion

The evolution from manual to automated box assembly has significantly benefited the packaging industry by enhancing efficiency, reducing costs, and contributing to sustainability. With ongoing technological advancements, the future of box assembly machines promises even greater improvements.