Revolutionizing Packaging with Automated Box Assembly Machines

Introduction: In today’s industrial landscape, where efficiency dictates market success, automated box assembly machines have become essential for businesses seeking to enhance their packaging operations. These machines are engineered to streamline the process of constructing boxes from flat sheets to finished products, significantly speeding up production while ensuring consistency and reliability. This article delves into the functionality and benefits of automated box assembly machines in modern manufacturing.

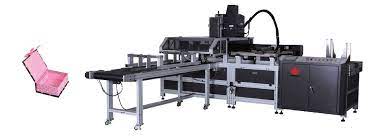

What is a Box Assembly Machine? A box assembly machine automates the creation of boxes, performing tasks such as folding, gluing, and sometimes sealing. These machines take flat, pre-cut, and scored cardboard sheets and transform them into ready-to-use boxes, eliminating the need for manual assembly. Designed to handle various materials and box designs, they are adaptable to a range of packaging needs.

Core Features:

- High-Speed Assembly: Box assembly machines can produce a large number of boxes in a short period, dramatically increasing productivity.

- Precision and Accuracy: Equipped with advanced technology, these machines ensure each box is assembled with precise folds and secure adhesives, resulting in high-quality packaging.

- Versatility: Many models can be adjusted to produce different sizes and types of boxes, making them suitable for diverse industries and products.

- Integration Capability: These machines can be integrated into larger packaging systems, aligning with other machinery for filling, taping, and labeling, creating a seamless packaging line.

Advantages of Using Box Assembly Machines:

- Enhanced Efficiency: Automating the box assembly process reduces the time from production to market, enabling companies to meet consumer demands more rapidly.

- Reduced Labor Costs: By minimizing the need for manual labor in box construction, these machines help lower operational costs and reduce the potential for human error.

- Improved Worker Safety: Automating the repetitive tasks associated with box assembly helps reduce workplace injuries related to manual labor.

- Sustainability: More accurate material use and reduced waste contribute to more environmentally friendly production processes.

Industrial Applications: Box assembly machines are incredibly versatile and find applications across various sectors:

- Retail and E-Commerce: Essential for businesses that require reliable packaging solutions to handle a high volume of shipments efficiently.

- Food Industry: Used for assembling cartons that are sturdy and safe for food products, maintaining health and hygiene standards.

- Electronics: Provides protective packaging that can be precisely tailored to secure fragile components.

- Pharmaceuticals: Ensures that packaging meets the regulatory standards for safety and tamper-evidence.

Conclusion: Automated box assembly machines are transforming the packaging industry by offering an efficient, cost-effective, and reliable method to meet the high demands of modern manufacturing. As companies continue to look for innovative ways to improve their operational workflows, the role of these machines becomes increasingly crucial. Investing in advanced box assembly technology not only boosts productivity but also enhances the overall quality and integrity of the packaging, which is vital for customer satisfaction and brand reputation.