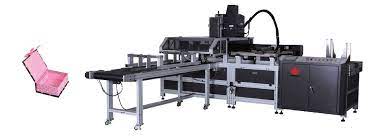

Paketleme Verimliliğini Artırma: Yeni Nesil Kutu Montaj Makineleri

In the rapidly evolving world of packaging, businesses continually seek solutions that not only streamline operations but also adhere to the growing demands for sustainability and precision. The latest advancements in box assembly machinery are setting new benchmarks in the industry, combining innovative technology with environmental consciousness to revolutionize packaging processes. This article delves into the state-of-the-art features of modern box assembly machinery and its impact on the packaging sector.

Innovative Features of Modern Box Assembly Machinery

Smart Automation: The heart of modern box assembly machinery lies in its smart automation capabilities. Equipped with advanced sensors and AI-driven algorithms, these machines can adjust operations in real-time, ensuring optimal efficiency and minimizing waste. This level of automation allows for faster setup times, quicker adjustments, and seamless production runs, catering to the dynamic needs of today’s packaging industry.

Connectivity and Integration: Integration with the broader manufacturing ecosystem is a key feature of the latest box assembly machinery. Leveraging IoT (Internet of Things) technology, these machines offer unparalleled connectivity, enabling remote monitoring and management. This feature ensures that box assembly processes are fully aligned with other production activities, enhancing overall operational efficiency and reducing downtime.

Eco-friendly Operations: Sustainability is at the forefront of new box assembly machinery designs. Manufacturers are now focusing on creating machines that consume less energy, utilize sustainable materials, and produce minimal waste. This commitment to eco-friendly operations not only helps businesses meet their environmental goals but also resonates with consumers increasingly concerned about sustainability.

The Impact of Box Assembly Machinery on the Packaging Industry

Enhanced Production Speed and Accuracy: The latest box assembly machinery significantly increases production speeds without compromising accuracy or quality. This efficiency is crucial for businesses looking to keep up with high demand and maintain a competitive edge in the market.

Customization and Flexibility: With the ability to handle a wide range of materials and box designs, modern box assembly machinery provides unparalleled customization options. This flexibility enables businesses to tailor their packaging solutions to specific product requirements, enhancing brand recognition and consumer satisfaction.

Reduced Operational Costs: By streamlining the box assembly process and reducing manual labor, the newest machinery models offer significant cost savings. Additionally, the reduction in material waste and energy consumption contributes to lower overall production costs, creating a more sustainable and profitable operation.