Transforming Packaging Lines: The Next Generation of Box Assembly Machinery

In the dynamic world of packaging, efficiency and innovation are paramount. Box assembly machinery, a cornerstone technology in the packaging industry, has seen groundbreaking advancements, propelling the capabilities of manufacturers to new heights. The evolution of these machines is not just a tale of technological progress but a response to the increasing demands for faster, more reliable, and environmentally friendly packaging solutions. Here’s a glimpse into how the latest technological advancements are reshaping box assembly machinery:

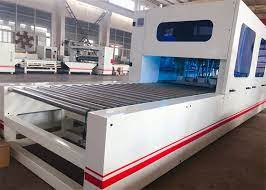

Automation and Robotics: The integration of sophisticated robotics into box assembly lines has revolutionized the speed and accuracy of packaging. These robots are designed with advanced sensors and AI algorithms, enabling them to adapt to various box sizes, shapes, and materials with minimal human intervention. The result is a significant increase in production rates and a reduction in errors and waste.

Customization and Flexibility: Modern box assembly machines are equipped with modular design principles, allowing for quick adjustments and changeovers. This flexibility means manufacturers can easily switch between different packaging types and sizes, catering to the bespoke needs of clients without the need for lengthy downtime or complex reconfigurations.

Sustainability Features: Today’s box assembly machinery is developed with sustainability in mind. Energy-efficient motors, regenerative power systems, and the capability to handle recycled and biodegradable materials are just some of the features that make these machines environmentally friendly. This focus on sustainability is in direct response to consumer demands for greener packaging options.

Connectivity and Smart Monitoring: Leveraging IoT technology, the latest generation of box assembly machinery offers enhanced connectivity, enabling real-time monitoring and analytics. This connectivity allows for predictive maintenance, reducing unexpected downtime, and optimizing overall production efficiency. Furthermore, data collected from these machines can be used to refine processes, ensuring continuous improvement.

Safety and Ergonomics: Enhanced safety features and ergonomic designs are central to the latest box assembly machinery. Safety sensors, emergency stops, and user-friendly interfaces ensure operator safety and comfort, reducing the risk of workplace injuries and improving productivity.

Quality Control Integration: Advanced vision systems and automated quality control checks are now integral components of box assembly machinery. These systems inspect each package for defects in real-time, ensuring that only products meeting the highest standards are dispatched. This integration significantly reduces the cost and time associated with manual quality checks.

The technological advancements in box assembly machinery underscore a significant shift towards more efficient, flexible, and sustainable packaging solutions. As manufacturers continue to innovate, the potential for further enhancements in speed, accuracy, and eco-friendliness looks promising. These machines are not just transforming packaging lines; they are setting a new standard for the industry, one that aligns with the evolving demands of businesses and consumers alike.