Box Assembly Machinery: Enhancing Packaging Efficiency with Advanced Technology

In today’s competitive marketplace, efficient and reliable packaging solutions are crucial for maintaining product integrity and optimizing the supply chain. Box assembly machinery has emerged as a vital component in the packaging industry, offering businesses the speed, accuracy, and flexibility needed to meet diverse packaging demands. This article explores the technical innovations and advantages of box assembly machinery, showcasing its significance in modern packaging operations.

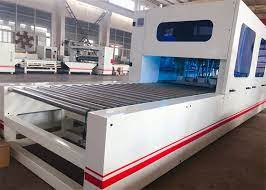

Technical Innovations in Box Assembly Machinery

Automated Precision: Modern box assembly machines are equipped with state-of-the-art automation technologies. These systems utilize precise mechanical movements and advanced sensors to ensure boxes are assembled accurately and consistently, minimizing material waste and maximizing production efficiency.

Versatility: One of the standout features of box assembly machinery is its versatility. These machines can handle a wide range of box sizes and styles, from simple cardboard cartons to complex, multi-part packaging. Quick-changeover capabilities allow for seamless transitions between different production runs, making it easier for manufacturers to switch between products and packaging types without significant downtime.

Integration Capabilities: Today’s box assembly machinery is designed for easy integration into existing production lines. With Industry 4.0 connectivity, these machines can communicate with other equipment and management systems, enabling synchronized operations and real-time monitoring. This integration is crucial for optimizing workflow and ensuring a smooth packaging process from start to finish.

Advantages of Utilizing Box Assembly Machinery

Increased Production Speed: By automating the box assembly process, manufacturers can significantly increase their production rates. This machinery is capable of assembling hundreds, if not thousands, of boxes per hour, far surpassing the output possible with manual assembly methods.

Enhanced Product Safety: Box assembly machinery not only speeds up the packaging process but also enhances product safety. By ensuring precise and secure assembly, these machines help maintain the structural integrity of the packaging, protecting the contents during transportation and storage.

Cost Efficiency: While the initial investment in box assembly machinery may be significant, the long-term cost savings are substantial. Automation reduces labor costs and material waste, while the increased production speed and reliability lead to improved overall efficiency and reduced operational costs.